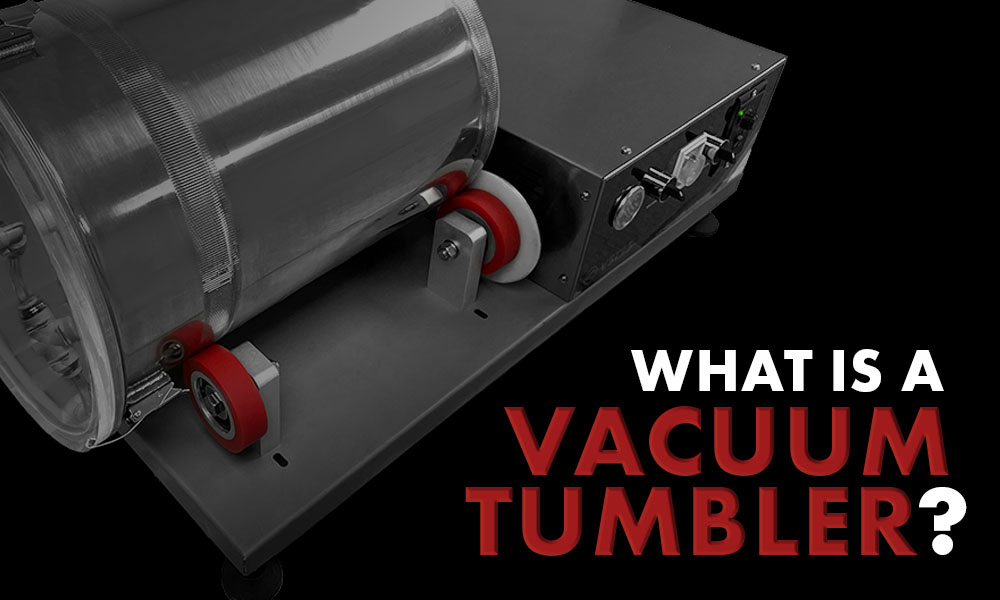

What is a Vacuum Tumbler?

“If efficiency and precision are among your top meat marination priorities, a vacuum tumbler is built for just that!”

Most meat produced today is processed. The goal is to allow meat manufacturers to sell their product at a higher price and satisfy customers by providing them with high quality products and easy food prep. But what if we tell you that a simple solution exists to produce commercial standard meat efficiently. A vacuum tumbler machine provides a gateway for you to produce top-quality meat, increasing your returns and saving time through the ability to produce in bulk faster than the traditional immersion marination!

Index

1) How Does a Vacuum Tumbler Work?

2) Features of a Vacuum Tumbler

3) Continuous vs Intermittent Vacuum Systems

4) How Vacuum Tumblers Produce Quality Meat

5) Benefits of Vacuum Tumblers

6) Factors Affecting the Product Quality

How Does a Vacuum Tumbler Work?

If efficiency and precision are among your top meat marination priorities, a vacuum tumbler is built for just that! Contents that can be marinated in a vacuum tumbler usually include meat such as chicken breasts, pork chops, fish, and more! Simply put, a vacuum tumbler applies a vacuum to the meat in an enclosed drum, opening the protein pores while horizontally rotating the drum to turn the meat over itself. This process pushes the marinade into the open pores creating thorough and consistent marination (review this video for an overview of how to operate vacuum tumblers) .

Features of a Vacuum Tumbler

A quick view at key vacuum tumbler features includes:

Stainless steel construction

Removable baffles to make cleaning easy

Analog gauge to achieve the desired vacuum level

Adjustable tumble time and speed

Our VacSeries vacuum tumblers include an oil-lubricated pump and moisture collection reservoir for durability

Continuous vs Intermittent Vacuum Systems

Every vacuum tumbler machine features internal or external vacuum systems. An internal vacuum is applied throughout the tumbling process by way of a snorkel while in an external system, the vacuum is applied then the source is disconnected before the tumbling cycle begins. Internally applied vacuums are categorized as either continuous or intermittent. A continuous vacuum sustains the same vacuum draw through the entire tumbling process. Intermittent vacuums offer rest times where the vacuum is released and the drum tumbling ceases for a few moments allowing the contents to shrink and then expand again as the vacuum and tumbling are reapplied. This creates a sponge-like effect to soak in the marinade.

Benefits of Vacuum Tumblers

1. Simple operation

2. Tumblers are efficient which increases product yield

3. Maximum marinade uptake which, in turn, reduces supply cost

4. Provides optimal flavor and tenderness which meets commercial-grade quality

5. Ideal for variable settings – restaurants, butcheries, meat manufacturers, etc.

How Vacuum Tumblers Produce Quality Meat

Protein Extraction: Vacuum tumblers utilize mechanical energy to initiate protein extraction for efficient tenderizing. Mechanical energy is kinetic energy plus potential energy. Kinetic energy is created as the meat tumbles over itself and hits the machine walls while potential energy is created as the baffles lift the meat producing the potential for the meat to fall. Together, they create mechanical energy that disrupts the protein bonds causing protein extraction. This disruption tenderizes the meat and releases an exudate solution which acts as a binding substance when heated which prevents loss of moisture while cooking.

Increased pH: For maximum tenderness and quality, a meat cut is expected to be in the healthy pH range of around 5.5-6.2, depending on the meat type. Marinating using salt solutions increases the pH level of the meat. Osmotic pressure increases meaning more water is absorbed, swelling the protein fiber lattice which increases the overall pH creating high-quality meat. These benefits are further amplified through vacuum tumbling as the vacuum draw and the tumbling allows maximum uptake of the solution.

Increased Marinade Pickup: While the machine drum rotates, the protein fibers break down allowing them to pickup more solution. Studies find that, depending on the process, a vacuum tumbling machine pickup is anywhere from 8-24% more marinade than immersion marinating!

Factors Affecting the Product Quality

It is important to understand that no universal marination recipe meets all factors that produce quality marinating results including flavor, tenderness, and product yield. However, studies have found patterns to take into account when setting the tumbling machine perimeters.

Cycle Time vs Tumble Speed

Tumblers are efficient with ideal running times ranging from 20 minutes to 8 hours as opposed to the standard 8-24 hours required from immersion marination. Cycle times and tumble speeds depend on your priorities as well as meat type. For example, longer cycle times would be considered for tenderizing tougher meats and shorter times for tender meat. Yet, if saving time is the priority over tenderizing, set a lower tumbling time but increase the reps per minute to force the marinade in more aggressively. Just be careful when it comes to tender meats like fish – high perimeters are not required for optimal flavor and tenderness!

Vacuum Type and Draw

Firstly, consider that an intermittent vacuum system will need longer tumble times to compensate for the rest times compared with continuous vacuum systems. Secondly, the optimal vacuum pressure is generally 15-20 inches Hg. For longer marinating times and softer meats such as chicken and fish, consider a vacuum draw within the lower range as you do not want too much protein disruption and ruin the product.

Temperature Control

Binding strength partially depends on the temperature of the content. The optimal protein extraction is produced at temperatures between 35-40°F. Some may achieve this by using refrigerated tumblers while others may cool the meat to around 25°F before tumbling as the temperature will rise during the tumbling process due to the transformation of mechanical energy to heat energy.

Vacuum Tumbler Drum Capacity

As explained, vacuum tumblers utilize mechanical energy by creating kinetic energy through motion. Kinetic energy partially depends on mass. Therefore, the more meat content in your drum, the better protein extraction will occur. But pay attention as every drum has a maximum capacity!

Additional Equipment to Retain Pickup

Brine Injector: Use a brine injector in tandem with a vacuum tumbler to obtain maximum pickup and even distribution increasing the product weight!

Chamber Vacuum Sealer: Vacuum package the product to retain the effects of marination by protecting the content from air, drying it out, and decreasing storage time. We can guarantee the VacSeries chamber vacuum sealers provide unmatched durability and up to 99.8% vacuum draw for the best results!

JVR VST25 – Vacuum Tumbler

$1,990.00

JVR VST50 – Vacuum Tumbler

$2,190.00

Questions?

We realize that many variables should be considered in the choice and operation of a vacuum tumbler. If you have further questions about vacuum tumblers, give us a call during our business hours or email anytime. We have every confidence in providing you with the information you need as we have specialized in vacuum packaging for over 52 years!