How to Replace the Lid Chamber Gasket – Vac100

“How do I replace the lid chamber gasket on my Vac100?”

A simple, yet tedious task to stop those pesky vacuum leaks around the chamber on your vacuum sealer. In this article, we review easy, yet effective ways to install your lid chamber gasket without unnecessary frustration.

When to Replace the Lid Chamber Gasket

The lid gasket slowly degrades over time due to the draw of the vacuum and continuous time under pressure. You may visually notice shredding and deformation of the gasket causing small vacuum leaks. Shredding does not mean you have a leak. It merely means you could potentially have a leak. Eventually, you’ll notice your pouches do not have all the air removed even though your operations/programs have not changed. This is a good sign that your unit has a leak and could potentially mean it’s time to install a new gasket.

However, keep in mind that this is only one variable that could be leading to a vacuum leak. Seal bar lift pistons could be leaking as well as any hose underneath the chamber. So, if you know that the leak is most likely happening by way of the gasket, then let’s move on to the next part! (If you do not know how to isolate the leak’s origin, please do not hesitate to call our offices for further guidance.)

Lid Chamber Gasket Removal

The first step in this process is simply to remove the old lid chamber gasket from your chamber vacuum sealer. Start pulling on it from one corner, and the entire thing will pull right out. Please note that your gasket’s ends may or may not have been glued together. (If you have a seamless lid chamber gasket, please disregard notes on glue.) This is not important. What matters is during reinstallation, the ends of the gasket fit snugly together.

Lid chamber gasket pictured above is the old-style gasket. Newer gaskets are seamless.

Gasket Shape

Before installing the gasket, take a moment to look at the end of the gasket. The shape looks like the number 6. The top of the 6, referred to as the tail, is going to be facing outward, away from the chamber. The base of the 6 should fit snugly into the channel. (This is only applicable to the non-seamless lid chamber gasket)

Installation

First, find a center point in the back edge of the channel. Take one end of the gasket and lay the flat bottom on the channel. Only compress about one inch of the gasket snugly into the channel.

Installing the Corners

Next, compress each corner of the gasket into the channel starting with the corner closest to where you inserted the first end. It’s important to pay attention to small details during this process. Ensure that the gasket is not overstretched. Doing so may cause it to lay too thin in the channel, therefore not fully engaging against the lid during a cycle.

Pull the gasket just taut enough to reach the first corner and then compress it into the corner channel. Then, bring the gasket down to the second corner nice and taut, but not overstretching. Push the base into the channel at that corner.

Continue the same process of bringing the gasket to the third and fourth corners and compressing the gasket only at the corners. Please note, at this point, the long edges of the gasket should not be compressed into the channel, only the corners.

Trimming the Gasket

Once the last corner is compressed, you’ll notice that your lid chamber gasket is a little too long. Take scissors to cut the excess, but give yourself an extra 1/32 or 1/64 of an inch beyond what you think you will need. After the gasket has been cut to size, take the end, pull it nice and taut, and compress one inch from the end into the chamber. Make sure the two ends of the gasket are pressed together creating a tight seal.

Completing Installation

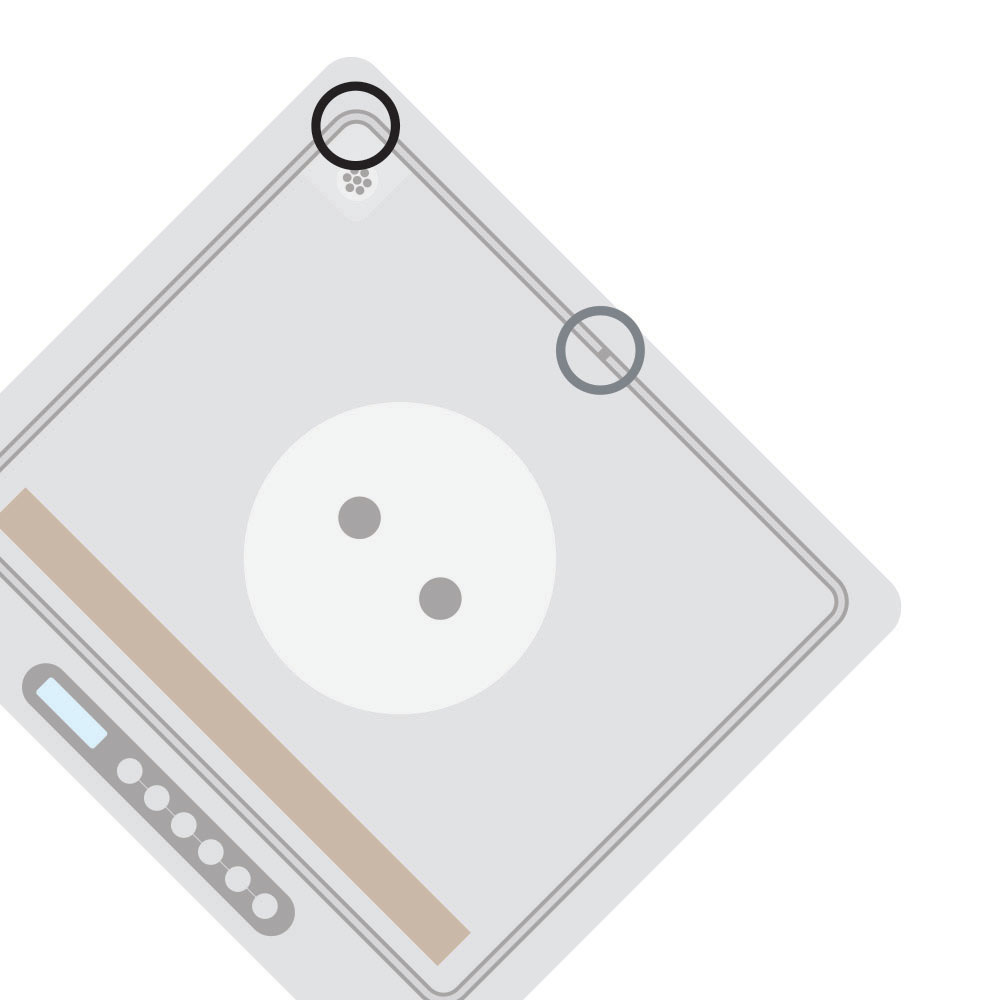

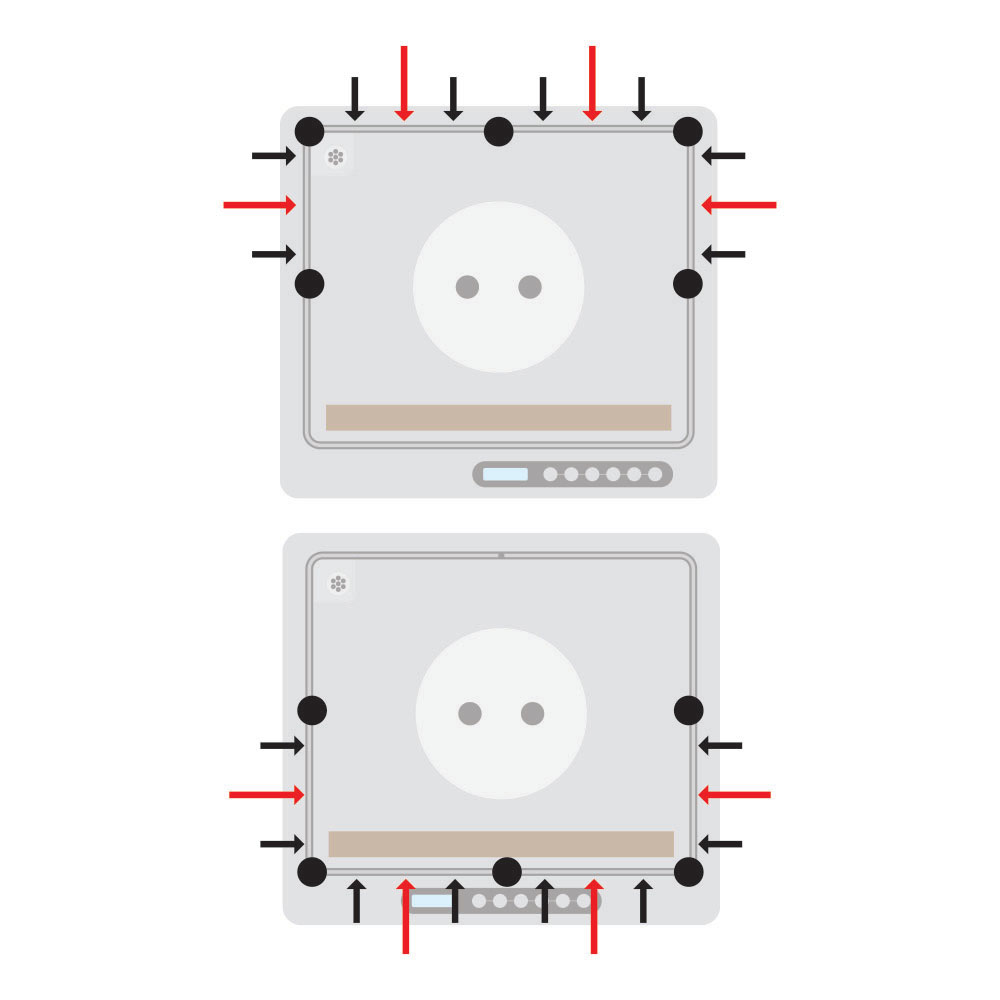

Now, return to the sides of the gasket where there is slack. First, compress the center of the gasket into the channel on all four sides. (SEE BLACK CIRCLES IN THE IMAGE) Next, put compression points in between each corner point and the center compression points creating eight more compression points. (SEE RED ARROWS IN THE IMAGE)

Now, you need to create four more compression points on each side of the gasket between the previously created compressions. (SEE BLACK ARROWS IN THE IMAGE)

Lastly, slowly work across the entirety of the lid chamber gasket and compress the remaining gasket into the channel. Run your thumb along each edge and ensure you’ve gotten rid of all the hills and valleys.

Inspection

Before running a cycle to review and inspect the seal, go around the perimeter of the gasket to search for wavering sections. Next, power on your Vac100 and simply close your lid. Once the lid compresses against the chamber gasket, visually inspect the gasket. Look for inconsistencies such as wavers, dips, and twists. The gasket should lay parallel to the channel’s path. After the cycle is completed and reviews are made, go ahead and make your adjustments.

To make adjustments in problem areas, roll that section of the gasket in the channel so that it’s even and consistent with the rest.

After adjustments are made, close the lid again and inspect the gasket. A sign that your gasket is installed correctly is when the entirety of the gasket is even and parallel in the channel. Once you see a perfectly tight seal, you’re all set.